Scientific Methodology

and Work Packages

Work Packages

Wp1 - management

Wp2 - State Of Art

Main achievements:

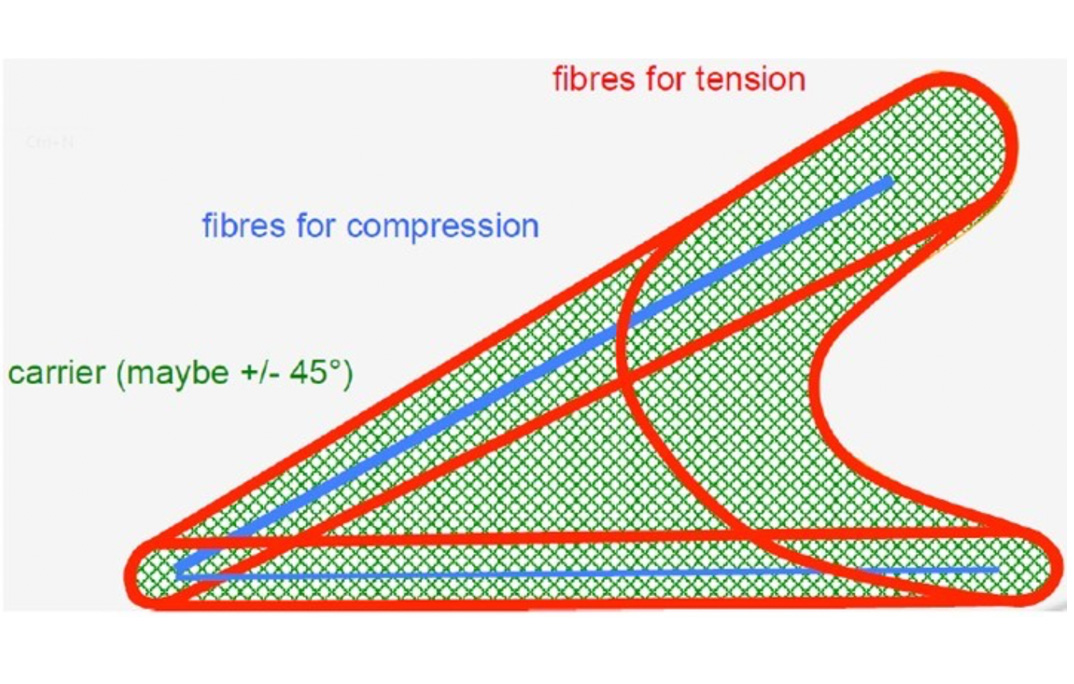

- Review of relevant available composite technologies

- Comparison between various manufacturing technologies to achieve project objectives

- Comparison between various materials, and material selection

- Comparison between various matrix systems

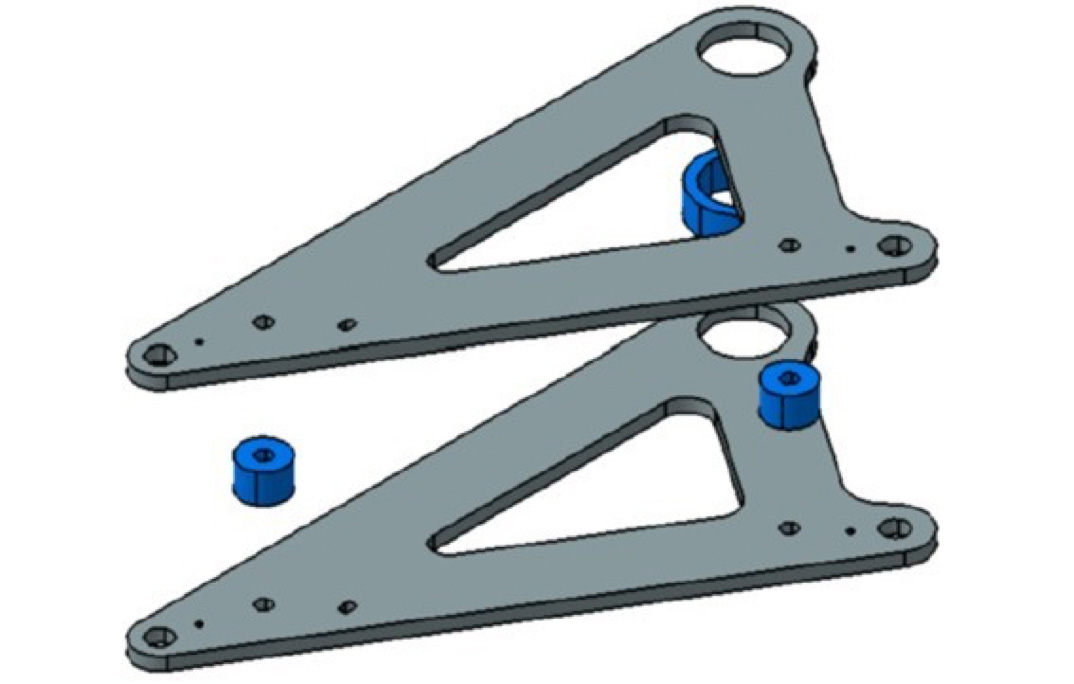

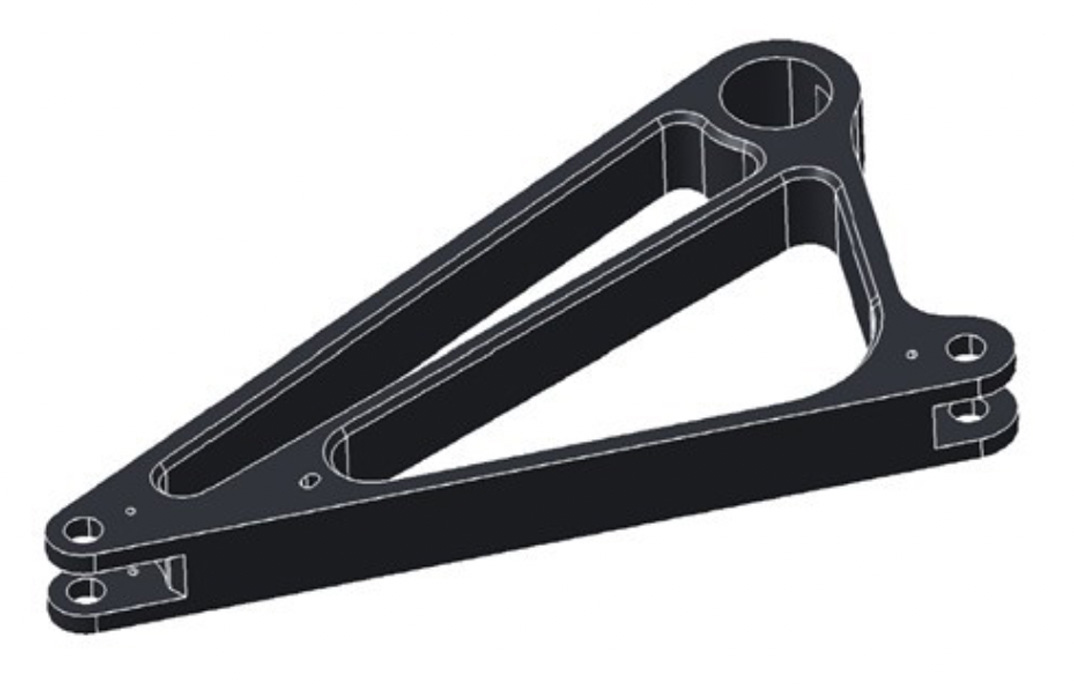

Wp6 - Manufacturing

Main achievements:

- Prototype manufacturing. Production of the first article

- Manufacturing and provision of test equipment

- Manufacturing of tools

Wp7 - Testing

Main achievements:

- Execution and verification of elements’ tests

- Execution and verification of demonstrator tests

Scientific methodology

Door linkage overlap technology was used to demonstrate joint of two identical sub preform to one preform